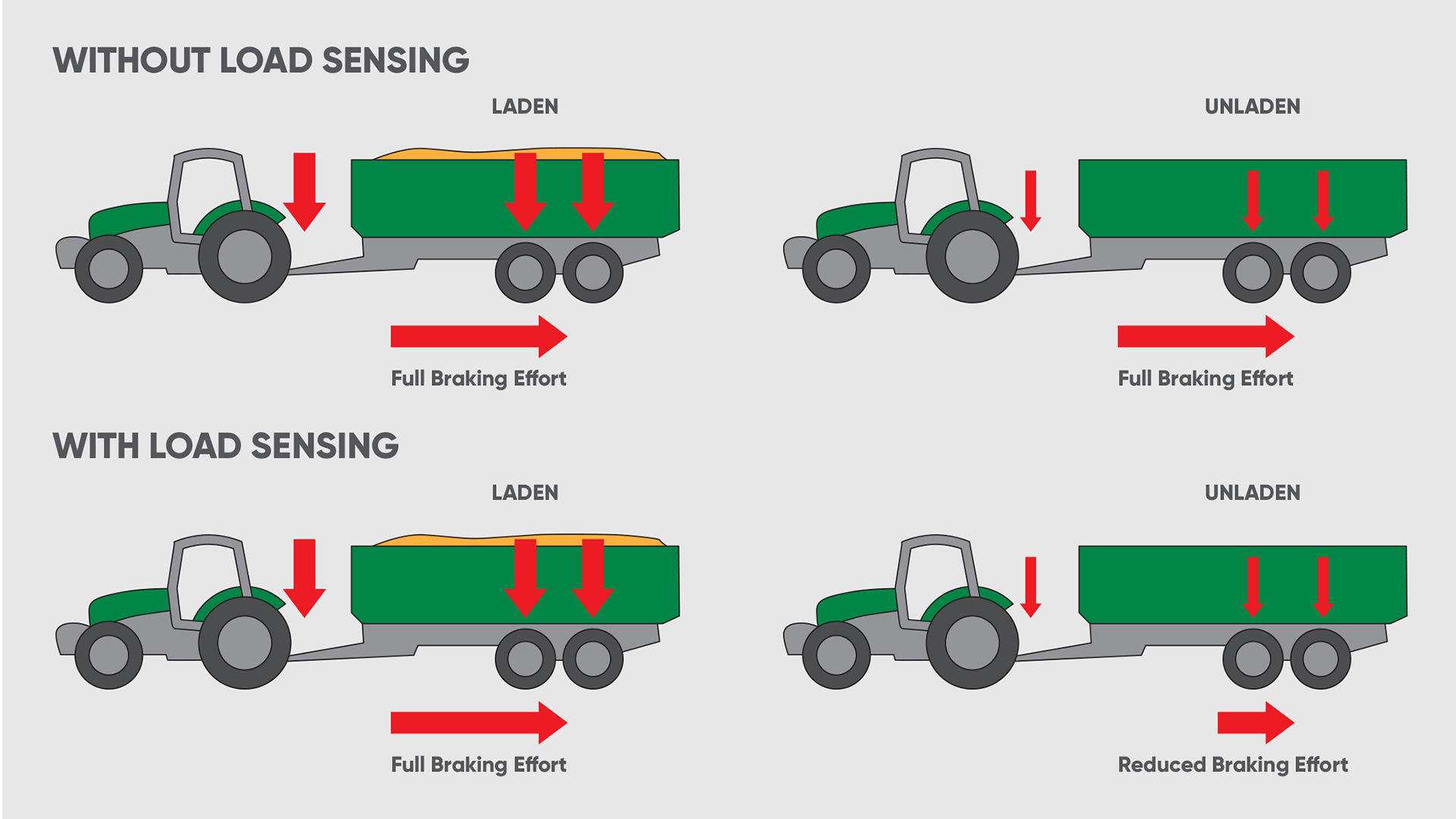

If your trailer travels on-road when laden and unladen, Load Sensing improves vehicle stability by preventing over-braking, wheel locking and excessive tyre wear during unladen or part-laden braking.

What does it do?

Load Sensing tells the trailer’s braking system how much weight / payload the trailer is carrying. When unladen or part laden, it reduces trailer braking effort to match the reduced axle load. However, the trailer still develops the same braking efficiency as when fully laden, matching that of the tractor.

How does it work?

The Load Sensing Valve (LSV) automatically adjusts trailer brake line pressure. Changing trailer payload (unladen-laden-unladen) causes the suspension springs to deflect. This movement operates the chassis-mounted LSV via a linkage or cable.

Unladen or part-laden, the LSV reduces the pressure directed to the brake actuators. This reduces braking effort in line with the reduced payload. The trailer develops the same braking efficiency as when fully laden.

Set correctly, LSVs can eliminate over-braking, wheel locking and excessive tyre wear during unladen and part laden braking.

LSVs can be ftted to both air or hydraulic braking systems.