Every year the UK produces 2.3 billion bags of sugar, for which British Sugar is the only buyer. Therefore, sugar beet growers must ensure they look after their beet to get the best price possible.

With this in mind, ‘just in time harvesting’ is an important strategy to maximise yields since it not only allows the crop to develop to more of its potential, but it also reduces sugar loss through respiration while beet is in store. However, for ‘just in time’ to work you need good communication between growers, lifting contractors, hauliers, the factories and principally reliable equipment that is gets the job done swiftly.

Designed for hauling beet

Our Beeteaper range is designed specifically for transporting and heaping beet. Like all Bailey trailers, Beeteapers are robust and reliable trailers built for hard work – RHS chassis, heavy-gauge sides and floors and 10-stud heavy-duty commercial axles fitted as standard.

Protecting the crop when unloading

By fitting longer side arms and rams Beeteaper trailers achieve a unique tipping angle of approximately 60°. Greater door clearance allows tractor operators to heap, level and scrape beet to a height of around 9’. This permits farmers to create a heap for beet to breathe by reducing the amount of heat generated, which in turn decelerates the rate of sugar loss.

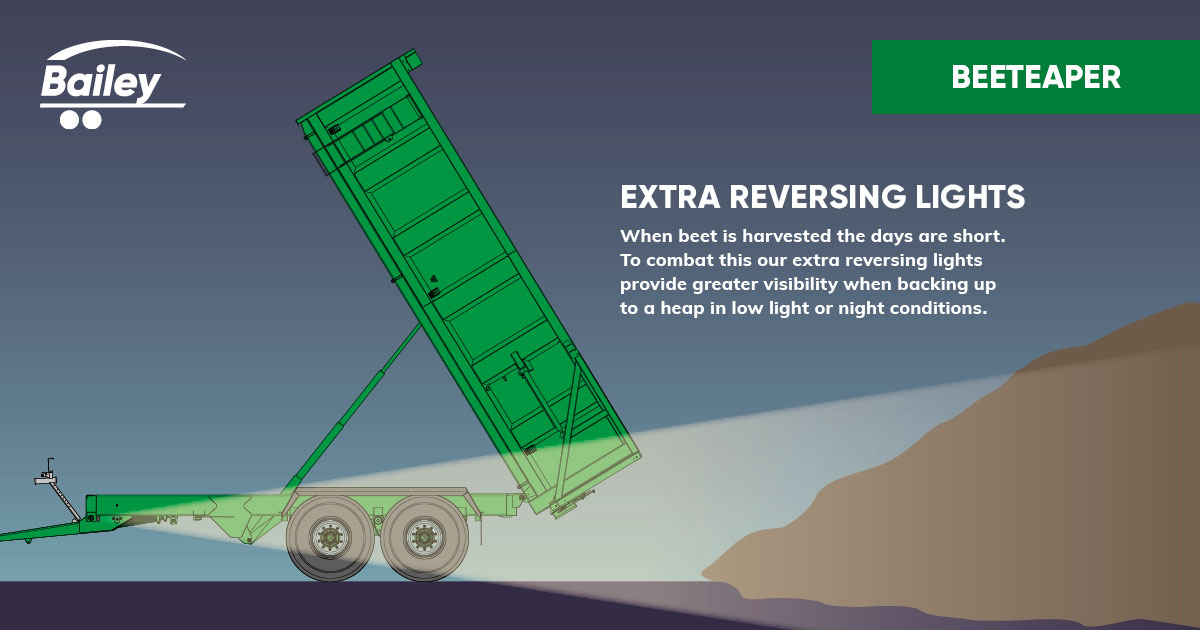

Making the most out of short days

Harvesting beet in the UK generally occurs when the daylight hours are short, making backing into a heap in low light or darkness a tricky manoeuvre. For this reason, we fit extra lights situated at the front of the trailer which illuminate the heap so that the tractor operator can see exactly where they are tipping.

Multiple uses add to Beeteaper’s versatility

Although our Beeteaper range is designed primarily for beet, it is just as dependable when transporting grain and other crops.